A Strategic Warning for C-Suite Leaders, Boards & Succession Planners

The U.S. manufacturing sector is experiencing an unprecedented shift. Automation, AI, and efficiency-first initiatives have delivered short-term productivity gains but they’ve also created a hidden risk that many executives haven’t fully confronted: the collapse of the manufacturing leadership pipeline.

The manufacturing leadership pipeline is already strained, but by 2030 it risks outright failure. In the past, future plant managers, operations directors, and continuous improvement leaders learned the business from the ground up starting in entry-level roles, managing shift challenges, understanding process flow, and absorbing the “tribal knowledge” of senior operators.

But in 2026 and beyond, a new threat is emerging: automation is eliminating the very roles that once produced tomorrow’s leaders. And in the drive for efficiency, companies are unknowingly cutting off the supply of people who will one day be responsible for running multimillion-dollar plants.

This article explores the data, the risks, the long-term consequences, and the strategies executives must implement now to avoid a leadership vacuum in 2030.

1. The Cost of Short-Term Efficiency: AI Is Hollowing Out the Workforce

While automation is rapidly transforming U.S. manufacturing, many leadership teams fail to see the second-order consequences of AI adoption.

The Data: AI Is Targeting Entry-Level Roles

A 2026 industry analysis reveals:

43% of manufacturing companies plan to replace entry-level roles with AI

Particularly in:

- Back-office support

- Scheduling

- Quality documentation

- Inventory handling

- Operational support assistants

- Basic machine-tending roles

This makes perfect financial sense on paper lower labor costs, fewer errors, higher uptime, and consistent workflows.

But there’s a strategic failure hidden within the cost savings.

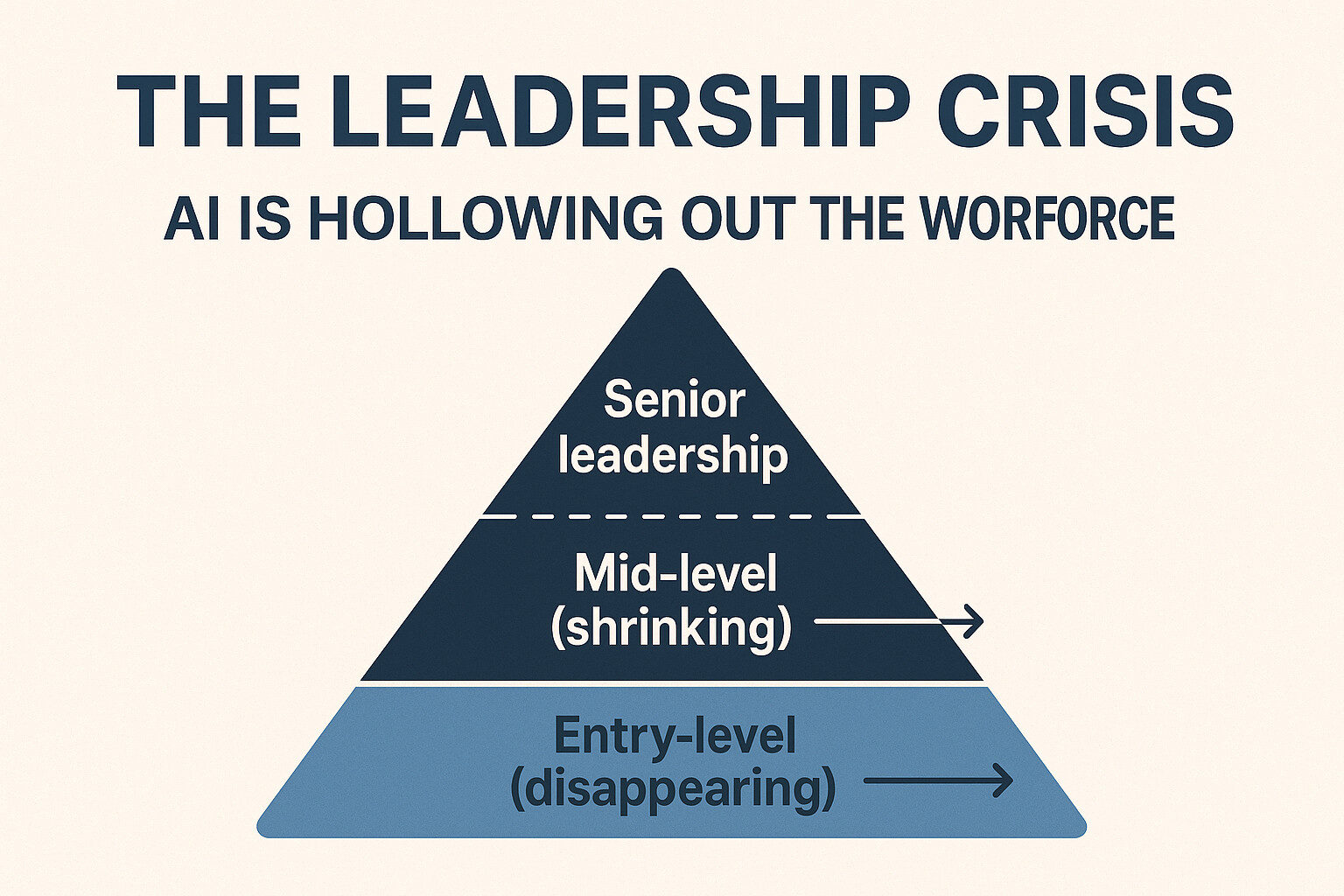

The Consequence: A “Hollowed-Out Workforce Structure”

The workforce pyramid that once fueled leadership continuity is collapsing:

✔ Senior leadership

⬇

✔ A shrinking mid-level (supervisors, tech leads, coordinators)

⬇

❌ Entry-level training ground disappearing

This creates what TalentTraction calls the Leadership Gap Funnel, where the traditional flow of talent no longer exists:

1990–2010 | 2010–2020 | 2020–2026 | 2026–2030 |

Strong base of entry workers | Reduced volume | AI replaces entry roles | No foundation for future leaders |

Companies now have:

✓ Senior executives and plant managers

✓ A handful of fast-tracked specialists

✘ But almost no one in development to replace them

This is the hollowed-out workforce crisis: the top is too heavy, and the base is too thin.

If the current trajectory holds, many U.S. manufacturers will reach 2030 without a viable bench of future plant managers or operational leaders.

2. Artificial Experience: The Rotational Program of 2030

If entry-level roles disappear, how can the next generation of manufacturing leaders learn the business?

Companies must artificially create the experiences that used to develop operators, supervisors, and future plant managers.

Rotational Programs Become the New “Entry-Level”

Forward-thinking manufacturers are already experimenting with:

- 6–12 month rotational leadership programs

- Job-shadowing sprints

- AI-augmented learning modules

- Virtual reality task simulations

- Immersive projects led by senior engineers and supervisors

These programs mimic the reality of entry-level work even if automation handles the operational tasks.

Example Rotational Modules

A future operations manager might rotate through:

- Inventory control (even if AI tracks inventory)

- Shift planning (even if algorithms schedule shifts)

- Quality review (even if inspection is automated)

- Machine setup simulations

- Conflict resolution on the floor

- Safety audits

- Lean kaizen projects

The goal isn’t to train people on manual tasks.

The goal is to expose them to friction, pressure, and the complexities of operations.

Why This Matters: AI Can Do the Work But Leaders Need Context

AI cannot teach:

- How a frustrated operator reacts when a shift gets reshuffled

- Why maintenance waits impact production morale

- How material shortages ripple across departments

- When a safety shortcut becomes a cultural hazard

Only experience teaches this.

If the organization removes the experience, it must recreate it.

Rotational programs are no longer “nice to have.”

They’re the new leadership pipeline infrastructure in an automated world.

3. The Boomer Brain Drain: A Knowledge Crisis in Motion

Baby Boomers, the last generation with deep, lifelong plant experience will be largely retired by 2026–2028.

The Numbers Are Stark

- Over 30% of U.S. manufacturing leaders are Boomers

- More than 3.5 million retirements are expected by 2030

- Only half as many younger workers are entering the industry

This “tribal knowledge collapse” creates operational risk across:

- Safety

- Process flow

- Quality

- Equipment nuance

- Materials behavior

- Production pacing

- People management

Automation can’t replace this experience.

AI can’t predict what it hasn’t seen.

Unless companies capture and transfer this knowledge, they will lose decades of operational insight permanently.

Mentorship Reimagined: From Knowledge Sharing to Institutional Preservation

Traditional mentorship is no longer enough.

Companies must design structured knowledge extraction programs.

High-Impact Mentorship for 2026–2030

A modern mentorship framework includes:

- Skill transfer checklists

- “War story” sessions

- Process walkthroughs

- Root cause problem-solving coaching

- “Day in the life” shadowing

- Leadership behavior modeling

- Scenario-based training

- Documentation capture sessions

- Micro-learning video libraries

The goal?

Prevent operational amnesia.

Knowledge must not retire when your experts retire.

4. The Strategic Rationale: Efficiency vs. Continuity

Manufacturing leaders are caught in a tension:

Short-term financial efficiency vs.

Long-term leadership continuity.

AI Reduces Cost But Also Reduces Leadership Readiness

AI eliminates:

- Easy tasks

- Repetitive tasks

- Learn-by-doing moments

But leadership is developed through:

- Conflict

- Ambiguity

- Constraint

- Pressure

- Exposure

- Situational judgment

AI has no instinct.

The next plant manager must.

If the entry-level disappears, the future leader disappears.

Plants will face:

- Supervisor shortages

- Weak mid-level bench strength

- Longer time-to-promote cycles

- Leadership bottlenecks

- Higher risk of operational failure

This is the 2030 Leadership Crisis and it’s mathematically unavoidable without intervention.

5. Succession Planning Strategies for 2026–2030

C-suite leaders and boards must adopt new succession planning strategies built for an automated era.

Here are the essential components:

A. Build a Manufacturing Leadership Pipeline with Intent

A modern pipeline includes:

- Technical rotations

- Leadership simulations

- Real-world projects

- Mentorship pairings

- Structured, AI-enhanced training

- Supervisory shadowing

Pipeline development must become a budgeted operational priority not an HR initiative.

B. Identify High-Potential Talent Early

Use predictive indicators like:

- Initiative-taking behavior

- Curiosity

- Cross-functional interest

- Adaptability

- Pattern recognition

- Ability to learn systems quickly

This talent pool should be monitored, coached, and cultivated annually.

C. Create “Leadership Acceleration Tracks”

These tracks fast-track high-potential employees into:

- Supervisor roles

- Shift coordinator roles

- Continuous improvement projects

- TPM teams

- Safety leadership committees

The goal?

Hands-on exposure + strategic thinking.

D. Implement Tribal Knowledge Preservation Protocols

Boards should require:

- Monthly knowledge-capture sessions

- Cross-training benchmarks

- Documentation audits

- Succession risk scorecards

- Mandatory mentorship participation

E. Redesign Workforce Structure to Restore the Middle Layer

Executives must avoid the “dumbbell organization” heavy at the top, heavy at entry, missing the middle.

A stable manufacturing organization in 2030 requires:

- Supervisors

- Team leads

- Coordinators

- Process owners

- Technicians with leadership potential

This middle layer cannot be automated away.

6. The Entry-Level Automation Risk: What Boards Must Understand

Executives often underestimate the long-term leadership risks of automating entry-level roles.

Entry-Level Automation Risk: Three Strategic Threats

1. Pipeline Destruction

No entry level → no supervisors → no managers → no plant leaders.

2. Culture Erosion

AI can run machines but can’t shape culture.

3. Operational Instability

When problems arise, human leaders must respond but fewer leaders will exist.

Boards should require AI adoption plans to include leadership continuity strategies, not just cost-saving ROI.

7. What the Smartest Manufacturers Are Doing Right Now

Top-performing U.S. manufacturers in 2026 are:

- Building AI-augmented leadership academies

- Integrating rotational simulation programs

- Pairing Boomer mentors with Gen Z apprentices

- Paying retention bonuses for tribal knowledge holders

- Creating knowledge vaults with SOP walkthroughs

- Incentivizing cross-functional training

- Rebuilding the supervisory middle layer deliberately

- Running succession risk audits every quarter

These companies will enter 2030 with a leadership surplus while laggards will struggle to fill supervisor roles.

8. What Happens If the Industry Does Nothing?

By 2030, companies that fail to rebuild their leadership pipeline will face:

- 40–60% vacancies in supervisory roles

- Higher safety incidents

- Lower morale

- Increased turnover

- Higher downtime during crises

- External hiring dependency

- Weak culture

- Poor innovation readiness

- Loss of institutional knowledge

- Difficulty scaling operations

Operational risk will be systemic not situational.

9. How to Prevent the 2030 Leadership Crisis

1. Acknowledge the risk

Automation ≠ leadership development.

2. Rebuild the leadership pipeline intentionally

Not through luck, but through structured systems.

3. Artificially recreate entry-level experience

Rotational programs are mandatory.

4. Capture tribal knowledge before it disappears

Boomer retirements peak in 2026–2028.

5. Invest in mentorship & succession planning

Knowledge must flow downward before it evaporates.

6. Restore the middle layer

Supervisors and leads cannot be optional.

7. Build a long-term leadership culture

Curiosity, resilience, problem-solving readiness.